Nitinol stents are delivered in a compact form and self-expand precisely at the target site, restoring blood flow with gentle, continuous force.

Description

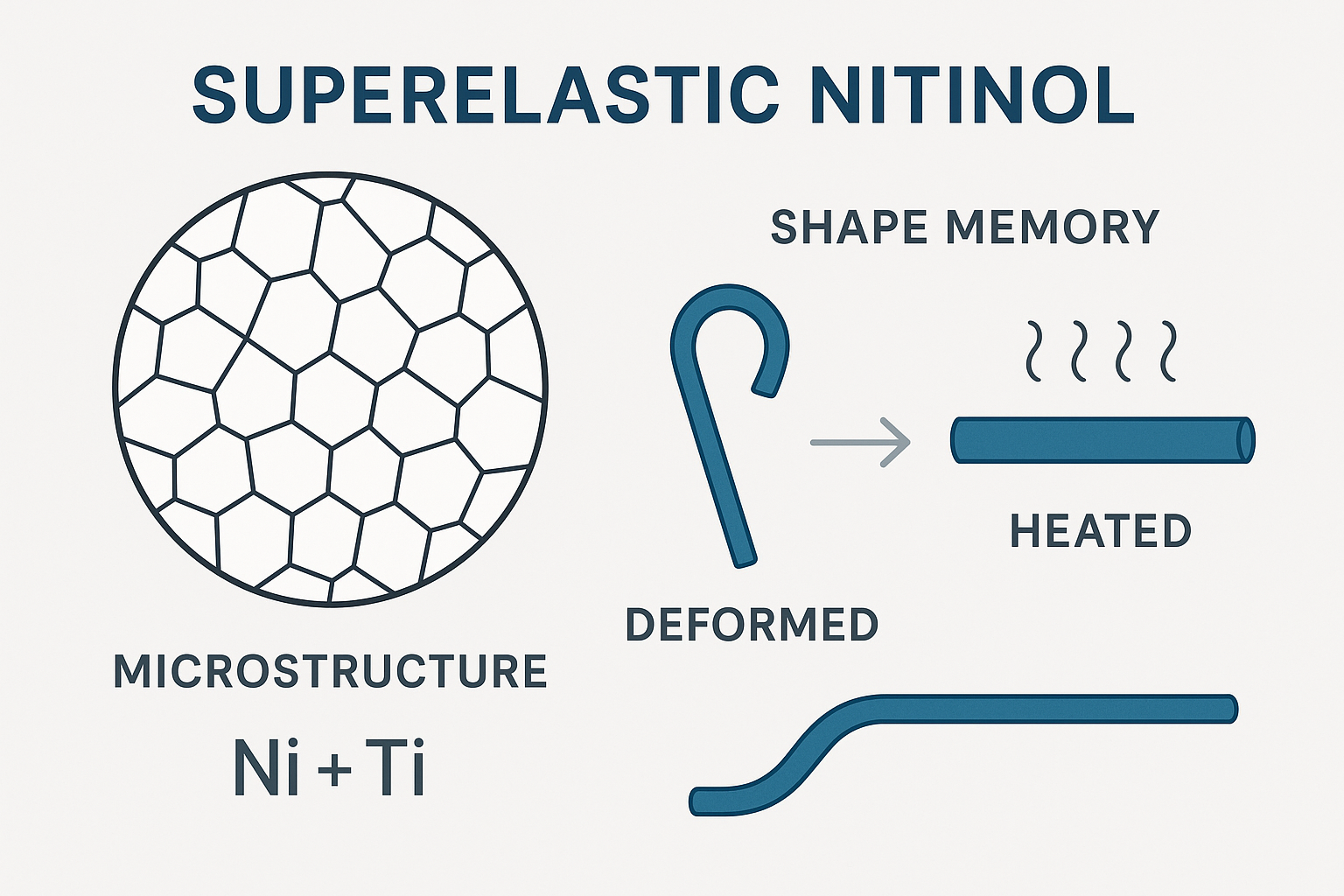

Introducing Nitinol: The Superelastic Smart Alloy for Medical Devices

Nitinol, an advanced alloy of nickel and titanium, exhibits distinctive properties ideally suited for medical applications. Its superelasticity lets it bend dramatically and snap right back to shape. Plus, with shape memory, Nitinol ‘remembers’ its designed form when warmed. These features let nitinol stents and other key devices work dependably inside the body. Medical engineers count on Nitinol for its flexibility, precision, and lasting strength.

Superelastic Nitinol Grades: Designed for Medical Excellence

We use high-performance Superelastic Nitinol grades that comply with stringent medical standards, including SE508 (ASTM F2063). We provide nitinol wire and tubing with outstanding corrosion resistance and proven biocompatibility, making them well-suited for extended implantation in the human body.With excellent fatigue life, they withstand repetitive motions such as blood flow and breathing. Sourced from trusted suppliers and processed with care, our Nitinol maintains its mechanical integrity and delivers superior performance in life-saving applications.

Nitinol Stents: Precision Support with Minimally Invasive Benefits

Nitinol stents revolutionize vascular care. Their superelastic nature allows for compression into ultra-small delivery systems, which are navigated through narrow vessels to reach targeted sites. Once released, the stent self-expands to restore blood flow by reopening blocked arteries. Unlike traditional materials, Nitinol adapts to natural vessel movement without kinking or permanent deformation, providing consistent support over time.

Wide Diameter Range: Custom Fit for Patient Anatomy

We manufacture nitinol stents in a full range of precision diameters to suit various clinical needs:

Neurovascular: 1.5mm–4.5mm (e.g., cerebral arteries)

Coronary & Peripheral: 5mm–10mm (e.g., femoral, iliac arteries)

Aortic: 20mm–45mm+ (for abdominal and thoracic applications)

Proper sizing is vital to achieve reliable device function and maintain patient safety.Our advanced manufacturing ensures consistent, accurate diameters tailored to your specifications.

Key Clinical Applications of Nitinol Stents

Nitinol’s versatility enables treatment across multiple specialties:

Peripheral Artery Disease (PAD): Opens blocked arteries in the legs and kidneys

Carotid Artery Disease: Reduces stroke risk by ensuring consistent cerebral blood flow.

Abdominal Aortic Aneurysm (AAA): Supports grafts that repair life-threatening bulges

Venous Disorders: Addresses iliac vein obstruction associated with May-Thurner Syndrome.

Biliary Obstructions: Opens bile ducts to relieve jaundice or infection

Digestive Tract Strictures: Maintains patency in the esophagus or colon

Beyond Stents: Expanding the Role of Nitinol in Medicine

Nitinol enables a wide range of medical devices beyond stents:

Guidewires: Engineered for accurate navigation through tortuous vascular anatomy, maintaining structural integrity under stress.

Vena Cava Filters: Temporarily capture blood clots using shape memory

Orthodontic Archwires: Apply gentle, constant pressure for effective tooth movement

Bone Anchors: Rely on body temperature to engage and provide stable fixation.

Heart Valve Frames: Provide flexible scaffolding in transcatheter valves (TAVR)

Surgical Instruments: Enhance control in minimally invasive procedures

Why Nitinol? Unmatched Performance Advantages

Superelastic Flexibility: Withstands extreme strain without permanent damage

Shape Recovery: Instantly returns to original form after deformation

Kink Resistance: Maintains integrity during catheter delivery

Biocompatibility: Proven safety for long-term implantation

CT Compatibility: Causes minimal imaging artifacts

Gentle, Constant Force: Supports vessels without trauma

Superior Fatigue Resistance: Performs reliably for years under cyclic loading

Our Expertise in Nitinol Medical Component Manufacturing

At Haolu Ni Ti New Materials Co.,Ltd, we specialize in transforming raw Superelastic Nitinol into advanced medical components. Our capabilities include:

Precision laser cutting of intricate stent geometries

Heat-based shape-setting for reliable memory activation

Meticulous electropolishing for smooth, biocompatible surfaces

Tight dimensional control and material property preservation

Compliance with ISO 13485 and FDA standards

From prototyping to full-scale production, we offer testing, validation, and technical support to ensure quality and innovation at every stage.

Partner with Us: Innovate with Nitinol, Improve Patient Outcomes

Superelastic Nitinol stents and components are revolutionizing minimally invasive care. Their distinctive mechanical behavior is crucial to the functionality of today’s advanced medical technologies. At Haolu Ni Ti, we deliver precision-engineered Nitinol solutions you can trust. Let’s create life-saving innovations together.

▸ Expert Guidance: 24/7 support via nitinolmetal.com

▸ Facebook account:Facebook

Reviews

There are no reviews yet.